Applications in motion control

Applications in Motion Control: The MICROingranaggi/Moog Italiana Collaboration

Testimonial by Roberto Donghi, Site Manager of Moog Italiana's Bergamo Facility, part of Moog Inc.: “Whether it's a motion control system based on electromechanical, hydraulic, or hybrid technology, we at Moog are the experts who provide support for every need.”

“Apart from technical expertise, MICROingranaggi's commitment to taking a journey with us was extremely important.”

Performance Issues

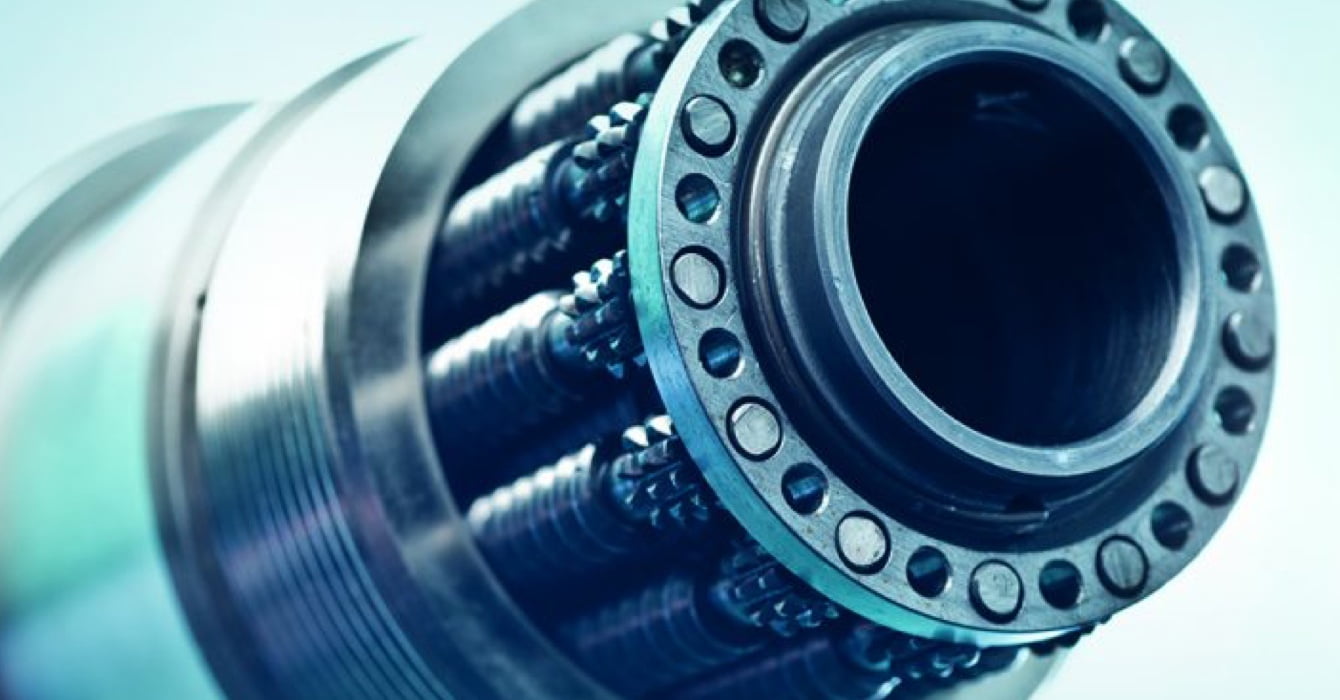

Moog is typically approached by companies that can't find "the solution" they need on the market. Developing solutions for motion control—specifically, screws in the case of Moog Italiana's Bergamo site—requires paying utmost attention to a variety of factors, ranging from performance to all related aspects, based on the needs and conditions of the frenetic and uncertain market. “About six or seven years ago,” explains Roberto Donghi of Moog Italiana's Bergamo facility, “we started experiencing a performance issue due to a design weakness in the roller screws we were manufacturing, particularly in applications that required higher and non-standard performance levels." This is how Moog Italiana turned to MICROingranaggi.

A Journey Together

“What's extremely important,” Donghi continues, “was MICROingranaggi's demonstration of their willingness to take this journey with us. Another crucial aspect, of course, was technical competence: we needed a technical partner who could offer the right suggestions at the right time. This led to the start of a true technological partnership based on the merging of our know-how, which allowed us to find the solution to our problems and achieve excellent performance even in applications that are generally very critical for roller screws.”