Our Company 4.0A Factory 4.0: Excellence in Mechanical Processing

Since 1973, we have been imagining, designing, and engineering precision micro-mechanical and electro-mechanical solutions.

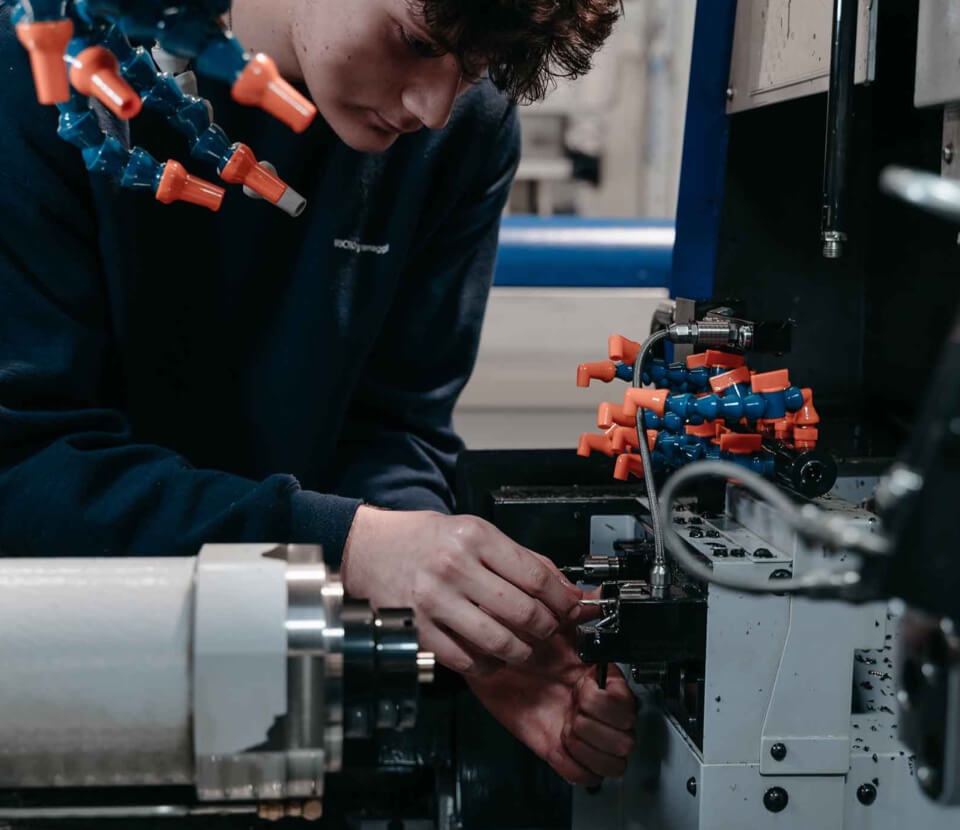

Our 4.0 workshop represents a center of excellence where technological innovation is the key to delivering high-quality solutions that remain consistent over time. Our dedication to precision and efficiency has made us, in our 50 years of history and experience, the ideal partner to tackle the most complex mechanical challenges.

Spread over an area of 3000 square meters in Buccinasco, on the outskirts of Milan, MICROingranaggi facility hosts over 20 CNC machines, divided between internal turning and gearing departments, 3 manual assembly laboratories, and a metrology room with controlled temperature and humidity for highly precise dimensional checks.

Every day, a team of 40 people is committed to delivering efficient and reliable mechanical solutions to meet the demands of the most discerning markets.

Technologies Serving Quality

Thanks to a recent investment plan targeted at 4.0 technologies, our factory has entered a new era of connectivity and innovation: every machine in our workshop is interconnected with management systems, and the data generated during the production process are processed to implement concrete actions and improve operational efficiency.

HistoryIn balance between tradition and future

The Beginning

After a career as a technical operator, Franco Garavaglia, nearing retirement, acquires the gear cutters from the workshop where he had worked for the last 10 years. Thus, MICROingranaggi is born, specializing in third-party gear cutting for watchmaking and precision instrumentation.

The First Automatic Machines

The entry of his son, Stefano, into the company marks the beginning of technological investments to modernize the machinery, with the purchase of the first automatic gear cutters. Production capacity increases, extending to the industrial automation and reducer sectors.

The Turning Department

Stefano Garavaglia officially takes over the Technical and Commercial leadership of MICROingranaggi, with Administrative direction entrusted to his wife and partner, Antonella Silvagni. The mechanical workshop moves to a new location and expands its services with the introduction of the turning department.

A New Location for New Departments

With constant growth, MICROingranaggi moves again, relocating to Buccinasco, in the current headquarters. Production is now based almost entirely on CNC machinery. The Metrology Room, Technical Office, and Assembly Department are inaugurated.

ISO9001-2008

MICROingranaggi obtains ISO9001-2008 certification for the first time.

Entering the Motion Market

The plant is expanded to the current 3,000 square meters, offering the opportunity to expand all company departments. With over 10 years of experience in designing and developing mechanical solutions, MICROingranaggi consolidates its intention to enter the motion and drive system market.

ISO9001-2018

MICROingranaggi obtains ISO9001-2015 certification for the first time.

Investments and Digitalization

MICROingranaggi initiates an ambitious project to modernize and digitize its production reality in line with new 4.0 technologies.

Industry 4.0 and Great Place To Work

Thanks to a careful investment policy in the previous 4 years, both production and organizational structure are revolutionized, with the introduction and replacement of 11 new 4.0 machines and an MES system, reaching 40 employees. MICROingranaggi obtains Great Place to Work certification for the first time.

50 Years of Activity, ISO9100, and ISO45001.

MICROingranaggi celebrates 50 years of activity and obtains ISO9100 certification for the aerospace sector and ISO45001 for safety for the first time.

MICROingranaggiApplications

One of our key competitive advantages is our ability to adapt to different sectors. With half a century of experience, we’ve supplied products for a wide variety of applications, from small kitchen appliances to aerospace components. We understand that each project has unique requirements, but it’s our experience across such diverse fields that allows us to transfer innovative solutions from one sector to another with ease, always delivering the highest level of expertise.

As of now, our revenue is distributed as follows:

Technical expertise at your service

Our technical office stands out for its expertise in designing a wide range of drive system solutions, including customized linear actuators and bespoke epicyclic gearboxes.